Performance management

Performance management mode has been executed since the company was established, it is a kind of advanced management mode and a new enterprise culture created by Hewitt Co., Ltd, US. This management mode is people oriented. To achieve the expected target, consensus must be reached, personal and company goals shall be confirmed, performance agreement shall be signed, and continuous feedbacks, instructions and assessments shall be made for continuous improvement. It has been found that an effective working environment comes from creative work done by the employee.

Management Information System

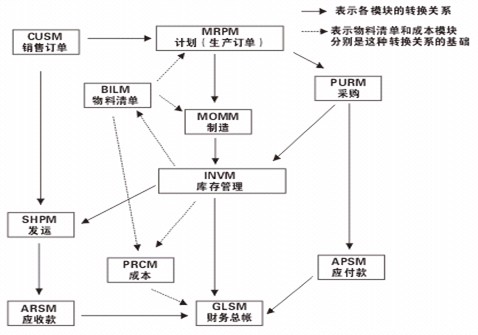

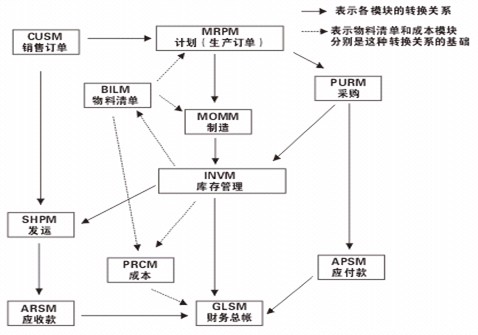

Our company has implemented management information system (MIS) since 2009 to realize smooth information stream, logistics and capital flow. We strive to improve capital and labor application; reduce cost; strength production and marketing cooperation and enhance competitiveness in the market; improve production and management level; enhance economic efficiency. We are approaching our goals: inventory reduced 20%, capital turnover quickened 45 days, production rate enhanced 10%-20%, product quality improved; purchase cost reduced 5% and purchase efficiency improved; delivery on time reached 85%-95%.Principle and major functional modules:See table below for major functional modules of MIS system.

Lean production

We introduce the Japanese Toyota management ideas, vigorously carry out the lean production. Its core is: the overall optimization, scientific configuration, eliminate waste, people-centered, to reach the acme of perfection as the goal. The implementation of the "just in time" and "Kanban" in the organization of production; in the labor force resources on the implementation of "one of the more", "expert" and "process management"; implementation of the "three self control" and "zero defect" quality management in logistics management; in the implementation of "zero waste.", "zero inventory"; implementation of the "zero fault" in the equipment management; in the knife mold tooling management on the implementation of "centralized grinding, stationary distribution" management mode.

6S management

Our company since 2009 the full implementation of the "6S" management system. "6S" management refers to the 6 aspects of enterprise based management, namely finishing (SEIRI), rectification (SEITON), clean (SEISO), clean (SETKETSU), quality (SHITSUKE), safety (SAFETY). As the first English letters, these 6 aspects are "S", referred to as "6S". Implementation of the "6S" management objective is to train staff starts from the minor matter, starts from oneself, to develop the habit of serious, reach a total quality improvement. To create a clean, neat, comfortable, reasonable, safe place to work and space environment for the whole company, will be a waste of resources to the lowest point, can greatly improve the work efficiency and enthusiasm of employees, improve product quality, improve the core competitiveness and corporate image.

Cash flow control

Market economy environment, the disorderly competition, accounts receivable "points" loss, "triangle debts" intensifies, the contradiction between production and capital of enterprises increasingly apparent. We learn from foreign advanced management experience, a bold innovation in financial management, cash flow control method. This new model of financial management, management accounting system not only meet the requirements of the United States of America, and to connect with the financial management of Western countries. Its core is the enterprise cash flow and the level of equity value appreciation. The effective implementation of the key cash flow control is the cash flow forecast, budget, target profit and cost management. Through the implementation of the cash flow control, greatly accelerated the turnover of capital, increase cash flow, equity value, enhance the enterprise's financial risk resisting ability and market competitiveness.

Performance management mode has been executed since the company was established, it is a kind of advanced management mode and a new enterprise culture created by Hewitt Co., Ltd, US. This management mode is people oriented. To achieve the expected target, consensus must be reached, personal and company goals shall be confirmed, performance agreement shall be signed, and continuous feedbacks, instructions and assessments shall be made for continuous improvement. It has been found that an effective working environment comes from creative work done by the employee.

Our company has implemented management information system (MIS) since 2009 to realize smooth information stream, logistics and capital flow. We strive to improve capital and labor application; reduce cost; strength production and marketing cooperation and enhance competitiveness in the market; improve production and management level; enhance economic efficiency. We are approaching our goals: inventory reduced 20%, capital turnover quickened 45 days, production rate enhanced 10%-20%, product quality improved; purchase cost reduced 5% and purchase efficiency improved; delivery on time reached 85%-95%.Principle and major functional modules:See table below for major functional modules of MIS system.

We introduce the Japanese Toyota management ideas, vigorously carry out the lean production. Its core is: the overall optimization, scientific configuration, eliminate waste, people-centered, to reach the acme of perfection as the goal. The implementation of the "just in time" and "Kanban" in the organization of production; in the labor force resources on the implementation of "one of the more", "expert" and "process management"; implementation of the "three self control" and "zero defect" quality management in logistics management; in the implementation of "zero waste.", "zero inventory"; implementation of the "zero fault" in the equipment management; in the knife mold tooling management on the implementation of "centralized grinding, stationary distribution" management mode.

6S management

Our company since 2009 the full implementation of the "6S" management system. "6S" management refers to the 6 aspects of enterprise based management, namely finishing (SEIRI), rectification (SEITON), clean (SEISO), clean (SETKETSU), quality (SHITSUKE), safety (SAFETY). As the first English letters, these 6 aspects are "S", referred to as "6S". Implementation of the "6S" management objective is to train staff starts from the minor matter, starts from oneself, to develop the habit of serious, reach a total quality improvement. To create a clean, neat, comfortable, reasonable, safe place to work and space environment for the whole company, will be a waste of resources to the lowest point, can greatly improve the work efficiency and enthusiasm of employees, improve product quality, improve the core competitiveness and corporate image.

Cash flow control

Market economy environment, the disorderly competition, accounts receivable "points" loss, "triangle debts" intensifies, the contradiction between production and capital of enterprises increasingly apparent. We learn from foreign advanced management experience, a bold innovation in financial management, cash flow control method. This new model of financial management, management accounting system not only meet the requirements of the United States of America, and to connect with the financial management of Western countries. Its core is the enterprise cash flow and the level of equity value appreciation. The effective implementation of the key cash flow control is the cash flow forecast, budget, target profit and cost management. Through the implementation of the cash flow control, greatly accelerated the turnover of capital, increase cash flow, equity value, enhance the enterprise's financial risk resisting ability and market competitiveness.