Quantitative Loading Control System

2014-1-15 11:30:51

Bottom loading arm has been widely applied in

petrochemical plants and oil refineries and depots to loading light oil

(i.e. gasoline, diesel, jet fuel, and naphtha) and benzene (benzoyl,

methylbenzene, dimethyl benzene). Our company designed an automatic

Quantitative Loading Control System which is fully functional, technical

advanced, structure reliable, and handle easier and work stable. This system

can complete parameter setup, data collection, flow temperature compensation,

quantitative control, procedure operation, overfill prevention and antistatic interlock, operation monitor,

and report printing etc, in loading process. It also offers communication

interface to connect external PCs. The quantitative oil loading control system

is very helpful for the bottom loading arm to give its maximum performance by

increasing the precision, speed, reducing human error and pollution, thus

improving the efficiency and saving energy. Our objectives are safety, labor

efficiency, ease-of-use, time saving, and ultimately higher returns.

Function

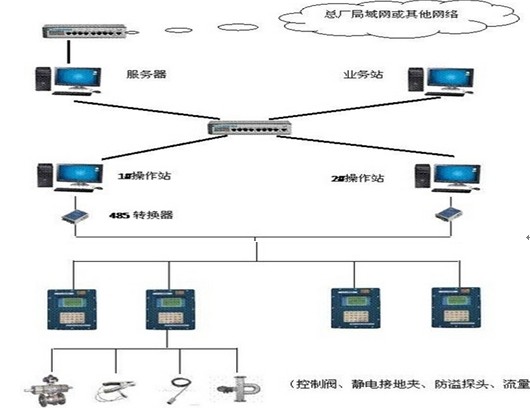

The system has distributed field control

and centralized remote control function. In order to ensure reliability, these

two control functions can be simultaneously available. When it occurs abnormal

cases in the control room, the operators can continue loading works at

individual loading lots by field controller.

◆Field controlled loading: Operators could conduct loading on-site

loading lots based on the Operator's Manual.

◆Remote controlled loading: All loading lots would be

accessed through the central control room where operators could conduct loading to single or multiple

tankers. The oil loading system data is consistent field showing data, and generates complete loading

information.

Characteristic

◆Distributed control and centralized

management

◆Flexible architecture that supports big expansions

◆Combination field condition and user’s need with Strong application

and effectiveness

◆Adjusted organize data display format

◆Automatic monitor and control valve on site

◆High reliability by rapid switching between

master/slave set

Applications

Petrochemical plants, large oil depots, light oil, benzene, industrial

chemicals, tank truck loading.

Technical Feature of Loading Control

System

◆Safety: Designed to be explosion-proof;

grounding connection and high anti-interference.

◆High adjustable precision

control and self-calibration.

◆Electro-hydraulic valves adopt

Variable time step flow control to ensure minimum flow after valve shut-off,

and achieve the maximum eliminating fluid hammer.

◆Automatic flow calculation and

control process adjustment ensures high precision.

◆Adopt Special communication

card offers fast polling which is several hundred times faster than ordinary

serial ports, allowing real time monitor of field oil loading process.

◆Electrostatic overfill

protection: When the electrostatic chuck is not properly connected and the

level exceeds that of overfill sensors, oil loading process will be rejected or

terminated, and alarm be sounded,

Intelligent

program control ensures precision of measurement.

◆Bi-level power source control

circuit: the electro-hydraulic valve and pump control circuit will be shut-off

at the ending of loading process to prevent false tripping caused by possible

controller failure.

◆Used Electronic switch for all

output control so as to ensure the controller long term reliability.

◆Multiple control mode, can

switch between manual/automatic two-ways.

◆Power fail protection:

Parameters backup any time and automatic restore after power on.

◆Status indicators of flow,

valve, operation, alarm, temperature, etc. for system fault diagnosis and

troubleshooting.

◆Lightning protection and filter

circuit guards the system against lightning and interference, enhancing

stability.

◆Real time temperature

compensation ensures precise oil loading density.

◆System self-checks ensures

correct controller behavior.

◆Online update for system

control program

- Previous:none!

- Next:none!