Steam-water separation tubular water-hammer heater

The steam-water separation tubular water-hammer heater enables the viscous liquid in the tank to heat up the viscous liquid, reduce the viscosity of the liquid and improve its fluidity by exchanging with the hot medium (usually saturated steam as the hot medium), so as to facilitate the delivery of the pump.

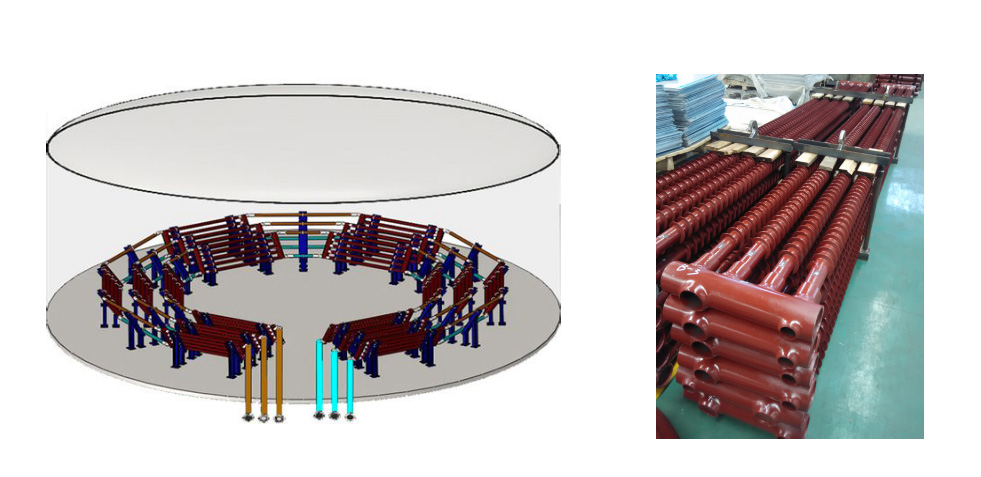

The steam-water separation tubular water-hammer heater is composed of several heating units, which mainly include columns, exhaust pipes and connecting pipes. The unique steam-water separation structure can completely separate the steam and water during the heating process, and the condensate can smoothly sink into the bottom of the riser, which not only has a good waterproof effect, but also has a very obvious energy-saving effect.

Main structure:

The main structure of steam-water separation tubular water-hammer heater is composed of heating pipe unit, connecting pipe, fixed support (leg), weld reinforcement sleeve and connecting fasteners.

Design features:

The overall structure of the autocratic collection pipe is in the shape of "non". It is made of carbon steel/stainless steel, and it is formed once by pulling the pipe, and the steam-water separation structure is set inside.

High-frequency welding winding finned tube has high heating efficiency, high steam utilization and large heating area.

The unique steam-water separation structure can effectively prevent "water hammer", reduce maintenance frequency, long service life and good safety

Component | Material & Specification | Remarks |

Heating manifold unit |

Material: carbon steel, stainless steel . Common specifications Ø57x6 | 1. Steam and condensate are effectively separated, water hammer is eliminated, heater leakage rate is reduced, maintenance frequency is reduced, service life is high, and safety is good;

2. The heater is modular and modular to effectively improve the installation efficiency of the heating device;

3. The unique spiral finned tube has a larger heat exchange area and higher heat exchange efficiency. The heating speed is 2~3 times of that of sectional heater and coil heater, saving about 30% of steam;

The unit and modular design of the heater can effectively improve the installation efficiency of the heating device. |

Steam nozzle | Material: carbon steel, stainless steel

. Common specification Ø 89x6 | |

Condensate connection | Material: carbon steel, stainless steel

. Common specification Ø 57x6 | |

support | Stainless steel, carbon steel |