Storage Tank Monitoring Control System

2013-9-10 14:37:16

System Overview

The CJ-STMCS Tank Yard Administration System is computerized tank yard monitor, control, and pipeline coordination system. High-performance industrial control computer, PLC, and field gauges are integrated by information sharing and coordinations to offer real time monitor, system management, interlock alarm, system diagnosis, log output, and other features. This industrial control and management application system was built on a sophisticated advanced industrial development software platform, with years of efforts. The development was based on various case studies on tank yard control systems, our years of experience on tank yard administration, latest advances in technologies, and had undergone constant improvements to better suit real applications at oil depots and refineries. The system greatly enhances tank yard automation, reduces labor force requirement and accidents, facilitating refined management, significantly improving quality and returns.

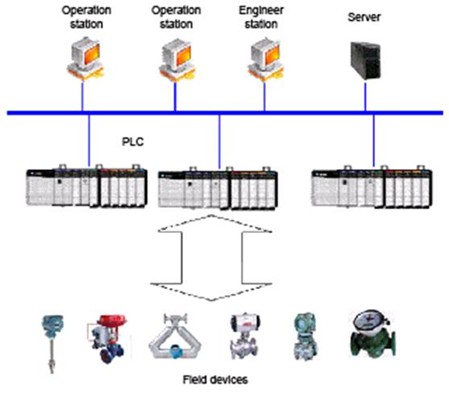

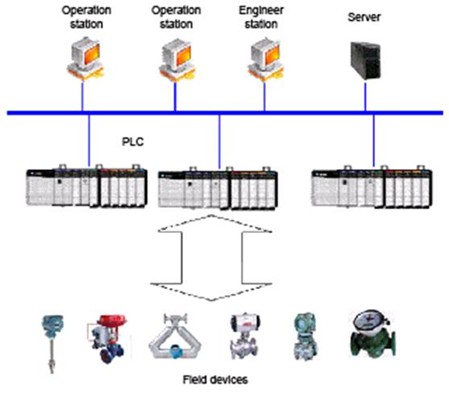

System Structure

System Features

System Features

Useful:User-friendly interface supports operations and functions required by oil depots production, safety, management, and decision making.

Mature:Based on advanced mature technology and design.

Safety:Safety control policies implemented.

Standardization:Based on international and industry-wide standards; unified management information data entries, classification & indexing standards, data and file formats, network communication protocols, and communication interfaces. Standardized software development ensures quality and easy future maintenance and upgrades.

Expansibility:Modular design supports good expansibility.

Cost effective:New equipments are chosen to maximize utilization of existing equipments, so as to provide optimal cost efficiency.

System functions

System login: this is used for identifying the operators’ identities who try to login the system, assigning related operation authorities, ensuring system safety.

Process flow display: this is used for displaying all kinds of production process flow chart, and because different color shows different on-site production status and device operation status etc., the operator can get the information of the actual production status and device status at one glance.

Tank level display: this is used for displaying oil level in tank and vapor consumption etc. in the screen of flow and level, and with the brightness indication, dynamical bar graph and color alarm information etc., the on-site production status will be shown.

Control operation such as opening/closing the valve: click the valve you want to open/close in the monitoring screen in the operation station, a dialog box will pop out from the screen, and control the on-site valve according to the prompt in the dialog box. Other control operations such as PID adjustment of pump are similar with this one.

Tank status management: this is used for displaying parameters showing if the oil level, related temperature and density in the tanks within the tank yard under control are within the related alarm range, and also displaying automatically if the tank is finished/semi-finished product, qualified/rejected product.

Oil blending: this generally includes crude oil blending, aviation kerosene blending and diesel blending and gasoline blending etc., which will be performed in different ways according to their specific characteristics.

Alarm display: alarm can be displayed in many ways by changing the graph color, showing the information in the alarm window. Alarm is designed to pop out in the current screen automatically if it is triggered on site no matter what kind of operation is being performed in the monitoring screen, so as to ensure high system safety and reliability.

System diagnosis: this is used for conducting online diagnosis and monitoring on the operation status of software and hardware in control system. When PLC malfunctions, this function will decide the fault type and then give the maintenance staff a prompt for troubleshooting.

Help function: this function includes system help and online help. System help offers help to the user in the form of electronic book. Information such as entire system functions, operation and usage, system structure, operating environment, prompt message and so on are described in detail in the electronic book, by which the operator can inquire various problem encountered in the work; No matter in what kind of monitoring screen, online help can be offered to the operator for helping them resolve the problem they encountered.

Operation record query: all kinds of operations executed by the operator can be inquired through the “operation record query” button in the flow screen. The operation record can be inquired by number, time or combination of the former two.

Abnormal action alarm and flow screening. Abnormal action alarm: alarm triggered by the abnormal action of the field device. Flow screening: incorrect operations by the operator will be screened and prompt will be given.

Report management system

Data entry function: this function includes data entry of inventory record, receipt and payment record, energy consumption report, oil blending report and so on. Data can be added (cancelled), modified (saved) when they are being input.

Data query function: receipt and payment record, inventory record, oil blending report can be inquired by time, tank number, destination or the combination of the former ones.

Report print function: this function can preview and print various kinds of reports according to time period.

Automatic data exchange function: field real time data can be automatically got and input for receipt and payment record and inventory record and so on. For inventory record, quantitative records can be added automatically at a regular time.

Data maintenance function: system tank data such as tank name, oil name, dynamic name, density-temperature coefficient table, volume-temperature coefficient table, and nominal tank number data such as oil tank capacity table, tank static pressure correction table, millimeter capacity table etc. can be checked by the operator. These oil tank data can be added or modified by administrator after inputting the password.

Password management function: password is set in the system to ensure safety of the system data. Only the administrator who know the password can add or modify the oil tank data and oil tank nominal data in the system.

Some basic system tools such as tank capacity calculation, simplified calculator, system time and date modification and so on, are provided for the operator to use.

System help function: hyper text help is made in the system to help the operator make the most of this system. Operators can check the help file by pressing F1 key any time they need help, and also can go to the specified contents by clicking the link set in the help file.

Application range

CJ-STMCS is suitable for tank yard related enterprises and departments such as refinery, chemical plant and oil depot, and also for other industrial production departments with many switches, various kinds of signals and with or without regular control rule.

The CJ-STMCS Tank Yard Administration System is computerized tank yard monitor, control, and pipeline coordination system. High-performance industrial control computer, PLC, and field gauges are integrated by information sharing and coordinations to offer real time monitor, system management, interlock alarm, system diagnosis, log output, and other features. This industrial control and management application system was built on a sophisticated advanced industrial development software platform, with years of efforts. The development was based on various case studies on tank yard control systems, our years of experience on tank yard administration, latest advances in technologies, and had undergone constant improvements to better suit real applications at oil depots and refineries. The system greatly enhances tank yard automation, reduces labor force requirement and accidents, facilitating refined management, significantly improving quality and returns.

System Structure

Useful:User-friendly interface supports operations and functions required by oil depots production, safety, management, and decision making.

Mature:Based on advanced mature technology and design.

Safety:Safety control policies implemented.

Standardization:Based on international and industry-wide standards; unified management information data entries, classification & indexing standards, data and file formats, network communication protocols, and communication interfaces. Standardized software development ensures quality and easy future maintenance and upgrades.

Expansibility:Modular design supports good expansibility.

Cost effective:New equipments are chosen to maximize utilization of existing equipments, so as to provide optimal cost efficiency.

System functions

System login: this is used for identifying the operators’ identities who try to login the system, assigning related operation authorities, ensuring system safety.

Process flow display: this is used for displaying all kinds of production process flow chart, and because different color shows different on-site production status and device operation status etc., the operator can get the information of the actual production status and device status at one glance.

Tank level display: this is used for displaying oil level in tank and vapor consumption etc. in the screen of flow and level, and with the brightness indication, dynamical bar graph and color alarm information etc., the on-site production status will be shown.

Control operation such as opening/closing the valve: click the valve you want to open/close in the monitoring screen in the operation station, a dialog box will pop out from the screen, and control the on-site valve according to the prompt in the dialog box. Other control operations such as PID adjustment of pump are similar with this one.

Tank status management: this is used for displaying parameters showing if the oil level, related temperature and density in the tanks within the tank yard under control are within the related alarm range, and also displaying automatically if the tank is finished/semi-finished product, qualified/rejected product.

Oil blending: this generally includes crude oil blending, aviation kerosene blending and diesel blending and gasoline blending etc., which will be performed in different ways according to their specific characteristics.

Alarm display: alarm can be displayed in many ways by changing the graph color, showing the information in the alarm window. Alarm is designed to pop out in the current screen automatically if it is triggered on site no matter what kind of operation is being performed in the monitoring screen, so as to ensure high system safety and reliability.

System diagnosis: this is used for conducting online diagnosis and monitoring on the operation status of software and hardware in control system. When PLC malfunctions, this function will decide the fault type and then give the maintenance staff a prompt for troubleshooting.

Help function: this function includes system help and online help. System help offers help to the user in the form of electronic book. Information such as entire system functions, operation and usage, system structure, operating environment, prompt message and so on are described in detail in the electronic book, by which the operator can inquire various problem encountered in the work; No matter in what kind of monitoring screen, online help can be offered to the operator for helping them resolve the problem they encountered.

Operation record query: all kinds of operations executed by the operator can be inquired through the “operation record query” button in the flow screen. The operation record can be inquired by number, time or combination of the former two.

Abnormal action alarm and flow screening. Abnormal action alarm: alarm triggered by the abnormal action of the field device. Flow screening: incorrect operations by the operator will be screened and prompt will be given.

Report management system

Data entry function: this function includes data entry of inventory record, receipt and payment record, energy consumption report, oil blending report and so on. Data can be added (cancelled), modified (saved) when they are being input.

Data query function: receipt and payment record, inventory record, oil blending report can be inquired by time, tank number, destination or the combination of the former ones.

Report print function: this function can preview and print various kinds of reports according to time period.

Automatic data exchange function: field real time data can be automatically got and input for receipt and payment record and inventory record and so on. For inventory record, quantitative records can be added automatically at a regular time.

Data maintenance function: system tank data such as tank name, oil name, dynamic name, density-temperature coefficient table, volume-temperature coefficient table, and nominal tank number data such as oil tank capacity table, tank static pressure correction table, millimeter capacity table etc. can be checked by the operator. These oil tank data can be added or modified by administrator after inputting the password.

Password management function: password is set in the system to ensure safety of the system data. Only the administrator who know the password can add or modify the oil tank data and oil tank nominal data in the system.

Some basic system tools such as tank capacity calculation, simplified calculator, system time and date modification and so on, are provided for the operator to use.

System help function: hyper text help is made in the system to help the operator make the most of this system. Operators can check the help file by pressing F1 key any time they need help, and also can go to the specified contents by clicking the link set in the help file.

Application range

CJ-STMCS is suitable for tank yard related enterprises and departments such as refinery, chemical plant and oil depot, and also for other industrial production departments with many switches, various kinds of signals and with or without regular control rule.

- Previous:Tank temperatur…

- Next:none!