Aluminum inner floating roof in hexagonal shape integrated with floating bowl and floating

2013-9-10 17:20:20

The main framework of the flow bowl type inner floating roof is the sandwich girder combined cover plate set up on the floating pipe. One/two sealing will be done around the tank wall to minimize the amount the volatile organic compounds (VOC) volatilize. Nowadays, inner floating roof sealing system has been widely used in storage of petrochemical products. With many years of experience in design, production and installation, our company can provide in time the most cost effective floating roof sealing system in various models with high quality and excellent design. All systems are complied with specification API 650 Appendix H, and all components are produced under our strict control, inspections and tests have been done to ensure their quality.

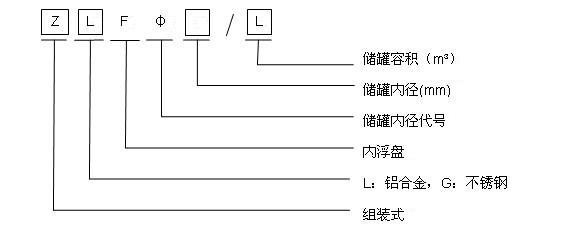

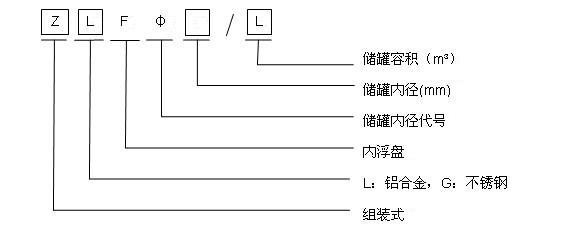

Model selection

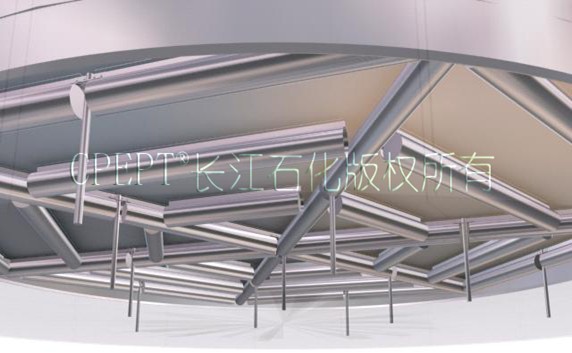

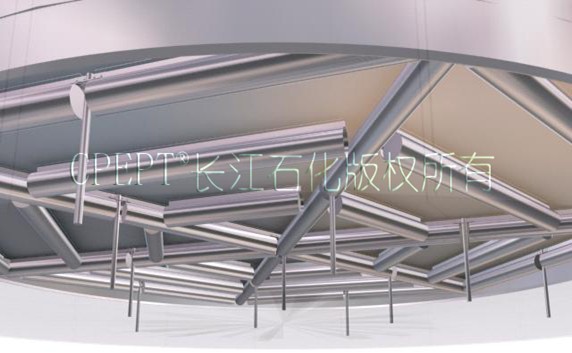

Structure

Structure

Characteristics

Characteristics

Main beam elements of the floating roof bone employs special section material under hot extrusion and structural elements integrates with floating elements into one.

Principle moment of inertia in the center of cross section is up to 416 cm4, which ensures very high overall rigidity level of product, the important technology of product and marking the domestic advanced level that firstly recognized.

Longitudinal connection of floating beam is designed as removable continuous beam, forming very stable triangle shape.

Floating beam subject to hot extrusion not only gives solution to potential safety problems of longitudinal welded seam in floating element, but also prevents material partly thinned, inconsistent between elongation rate and strength as well as stress corrosion caused by some cold working that generating serious deformation.

Floating beam end applies shallow drawing, internal pressure sealing and end sealing to solve the inevitable thin aluminum welding problem confronting the outer-sealed end. Imported TIG applied to this product can use high welding current with depth of weld penetration ≥2 mm to ensure welding quality.

Wall thickness of floating bowl of the floating beam is designed 1.2 mm, while actual thickness is 1.4 mm, thicker than 1.2 mm required in GB50341-2003.

Center plate and vent valve combine into one with compact structure and better balance performance.

Aluminum material of the floating roof applies 6063T5 malleable aluminum alloy or 3003H24 rust-proof aluminum alloy with the surface subject to anodic oxidation treatment, possessing good rigidity and anticorrosion performance.

All floating beams pass hydrostatic test for air tightness and random sampling inspection conducted by Hunan Technical Supervision Bureau.

Model selection

Main beam elements of the floating roof bone employs special section material under hot extrusion and structural elements integrates with floating elements into one.

Principle moment of inertia in the center of cross section is up to 416 cm4, which ensures very high overall rigidity level of product, the important technology of product and marking the domestic advanced level that firstly recognized.

Longitudinal connection of floating beam is designed as removable continuous beam, forming very stable triangle shape.

Floating beam subject to hot extrusion not only gives solution to potential safety problems of longitudinal welded seam in floating element, but also prevents material partly thinned, inconsistent between elongation rate and strength as well as stress corrosion caused by some cold working that generating serious deformation.

Floating beam end applies shallow drawing, internal pressure sealing and end sealing to solve the inevitable thin aluminum welding problem confronting the outer-sealed end. Imported TIG applied to this product can use high welding current with depth of weld penetration ≥2 mm to ensure welding quality.

Wall thickness of floating bowl of the floating beam is designed 1.2 mm, while actual thickness is 1.4 mm, thicker than 1.2 mm required in GB50341-2003.

Center plate and vent valve combine into one with compact structure and better balance performance.

Aluminum material of the floating roof applies 6063T5 malleable aluminum alloy or 3003H24 rust-proof aluminum alloy with the surface subject to anodic oxidation treatment, possessing good rigidity and anticorrosion performance.

All floating beams pass hydrostatic test for air tightness and random sampling inspection conducted by Hunan Technical Supervision Bureau.

- Previous:none!

- Next:Inner floating …